Abrasives

3M began as an abrasives manufacturer. For more than a century, we have refined our original technologies and complemented them with breakthrough inventions developed by other 3M businesses. Today, our abrasives rely on traditional strengths such as adhesives and coating as well as the most modern technologies-from microreplication to ceramics and nonwoven materials. The result is a comprehensive range of abrasives that shape, finish and polish with ease and precision.

Acoustic Control

Loud, unpleasant noises aren't just irritating-they are also a threat to our health and safety. 3M has engineered select nonwovens, viscoelastic polymers and other materials to absorb sound, dampen vibration and control undesirable noise. In automobiles these materials create a quieter passenger compartment. In computer disk drives, they reduce irritating sounds and help increase access speed and storage capacity. In the workplace they reduce distraction, protect hearing and allow communication.

Adhesives

So strong they can hold a structural panel for the life of a building... so gentle they yield to a child. Because 3M adhesives have been engineered to fit our customers' needs, they are used in such diverse products as airplanes and cell phones, automobiles and medical dressings. We excel in curable adhesives and epoxies. And, of course, pressure-sensitive tapes, which 3M invented more than 80 years ago.

Advanced Materials

When 3M scientists begin work on a customer's problem, they draw on a remarkable array of advanced and specialty materials: polymers, composites, ceramics, fluoromaterials, nanomaterials and more. Our labs constantly add to this palette with new formulations and breakthrough modifications of existing materials. And 3M is unmatched in the application of these novel materials to the demands of real-world manufacturing.

Analytical Science & Technology

New-to-the-world technologies generate solutions for our customers-and a host of questions for our scientists. What is this? How does it work? Can we make it better? To answer those questions, 3M has developed an unrivaled capability for measuring, characterizing, and understanding materials and processes. With resources located around the world, 3M scientists can draw on our analytical strengths during all phases of product development, from concept through commercialization and manufacturing.

Application Software

Application Software controls, monitors, interacts with, and enables many 3M innovations ranging from Air Filtration to enterprise-wide RFID solutions for tracking medical records. Application Software may run within a web browser, on standard desktop computers and hand-held devices, or may be embedded in special purpose electronic hardware and systems. 3M utilizes state of the art tools and techniques to develop application software that is robust, secure, and easy-to-use.

Biotechnology

To create products for the health sciences, 3M applies its unusual combination of strengths in material science, surface characterization, filtration and biology. Among the results: remarkably durable dental restoratives, biocompatible surgical tapes and dressings, transdermal patches for drug delivery, antimicrobial cleansers, and sterilization sensors.

Ceramics

3M started here, turning minerals into sandpaper. Over more than a century, we have forged inorganic ceramic materials into a surprising range of products. The rugged granules that protect your roof. The complex touch screen at your ATM. The aesthetic dental restorative and the coarsest abrasive. The brilliant bead in that defines your lane on a rain-soaked highway and the ultra-strong fiber woven into a power line-these are all derived from 3M's long history in inorganic ceramics.

Drug Delivery

Pharmaceuticals can enhance and sometimes even save lives. It is important that they are delivered in the correct dose, to the correct location, at the correct time. 3M has been a pioneer in the development of metered-dose inhalers (for delivering drugs to the respiratory tract) and transdermal patch systems. Today, our expertise in formulation chemistries and drug delivery technologies is complemented with decades of experience in regulatory affairs, quality assurance and precision manufacturing.

Display

3M display materials manipulate the transmission and reflection of light. By combining our expertise in multilayer films, lenses and microreplication, we are able to increase the clarity, durability or brightness of virtually all types of electronic displays-from liquid crystal displays in handheld devices, to LCD monitors and televisions, to gigantic projection displays. These materials are also used in privacy filters for laptop computers and for automated teller machines.

Dental & Orthodontic Materials

3M introduced the first tooth-colored restorative material in 1964-a breakthrough that addressed patients' concerns about aesthetics and dentists' demands for a durable material. Since then we have drawn on advances in chemistry, biology, ceramics and digitization to become a world leader in dental composites, adhesives, impression materials, orthodontic supplies and other products. In particular, we have pioneered the use of highly viscous restorative materials that are cured quickly and comfortably in the patient's mouth and impression technology that produce accurate replicas of the patient's dentition.

Energy Components

As the world searches for new ways to generate and store energy, it turns to 3M technology. The company is a global leader in fuel cell components, particularly in the design and manufacture of cost-effective membrane electrode assemblies. We are also active in the development of lithium ion materials for battery systems. In the photovoltaic industry, 3M is advancing technologies (including barrier films and Fresnel concentrator lenses) and supplying products such as very high bond and conductive foil tapes.

Electronic Materials

Advances in electronic components-from semiconductors and interconnects to data storage and displays-often begin with breakthroughs in the organic, inorganic and metallic materials from which these components are fabricated. 3M contributes to improvements in manufacturing and performance by applying its strengths in many of the other building blocks of today's electronic devices, including fluorochemicals, adhesives, abrasives, membranes, electrodes and electrolytes.

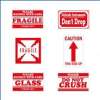

Flexible Converting & Packaging

For more than half of 3M's products, the last step in the manufacturing process is the conversion of a film, abrasive, tape or other material into the specific shape and size that a customer requires. Our ability to rapidly reconfigure how a product is cut, shaped, and finished allows for efficient customization with consistent quality. And this manufacturing agility is matched with capacity for flexible packaging that preserves and protects the finished product-and the branding strategy of the seller.

Flexible Electronics

Using advanced, proprietary materials and manufacturing techniques, 3M has become a pioneer in the manufacture of electronic circuitry on flexible polymer films. Ink-jet printer cartridges were among the early uses of these low-cost, lightweight, bendable circuits. Today, this technology is also used in hard disk drives, medical diagnostic devices, large flat-panel displays and other applications that require reliability and flexibility.

Films

3M's engineered films serve a vast multitude of uses. One product line enhances the brightness in LCD displays while another blocks the sun from coming through windows. 3M films are used to create building-sized graphics and to prevent graffiti. Some are single-layered with humble applications and others combine hundreds of layers that are tuned to transmit or reflect specific wavelengths. Still other films provide very high barriers to oxygen and moisture-a requirement in next-generation electronic displays.

Fluorinated Materials

3M fluorochemicals are the active materials in 3M's extensive line of protective coatings. They are also used as thermal management fluids and as surfactants that improve the flow of high performance paints and coatings. Dyneon fluoropolymers have outstanding temperature and chemical resistance making them ideal for many products that operate in extreme and hostile environments. They are used in wire coatings, seals, gaskets, non-stick coatings, fuel hose liners and other critical, high performance applications.

Filtration, Separation & Purification

Pharmaceutical, food and specialty chemical manufacturing demand components of the highest purity. To meet the rigorous standards of these and other industries, 3M offers multiple options-including electret, microporous membrane, carbon and nonwoven fiber technologies-for liquid and gas filtration and separation. This expertise has also been applied to 3M's personal respirators and masks, consumer air filters for homes and cars, and home water treatment systems.

Imaging

3M understands visual communication. We made the first thermofax machine for transmitting images. We redefined advertising with the first digitally printed, wall-sized graphics. We invented multilayer optical films that create crisp, vibrant images for electronic displays and counterfeit-resistant security marks. We've refined our inks and pigments to ensure true, bright colors that last, even under the harshest conditions. Building on decades of experience in print and digital technologies, 3M continues to introduce sophisticated films, inks and software for print, electronic displays and signage.